The Importance of Fan Selection: Using Proper Design Approaches in Determining Duty Point and Making Suitable Fan Selection

In various industrial and commercial applications, the selection of fans plays a pivotal role in ensuring optimal airflow, temperature control, and ventilation.

The efficiency, performance, and reliability of these fans are essential to the overall success of these systems. One key aspect of fan selection that often goes overlooked is the importance of using proper design approaches in determining the duty point and plotting it on the fan curves.

What is duty point :- in the aspect of ventilation engineering, the objectified airflow rate and system pressure loss (static pressure or total pressure) often are referred to as the duty point. A fan curve depicts duty pointIn this article, we will explore why fan selection must be approached with careful consideration of these factors.

Understanding the Basics: Fan Curves

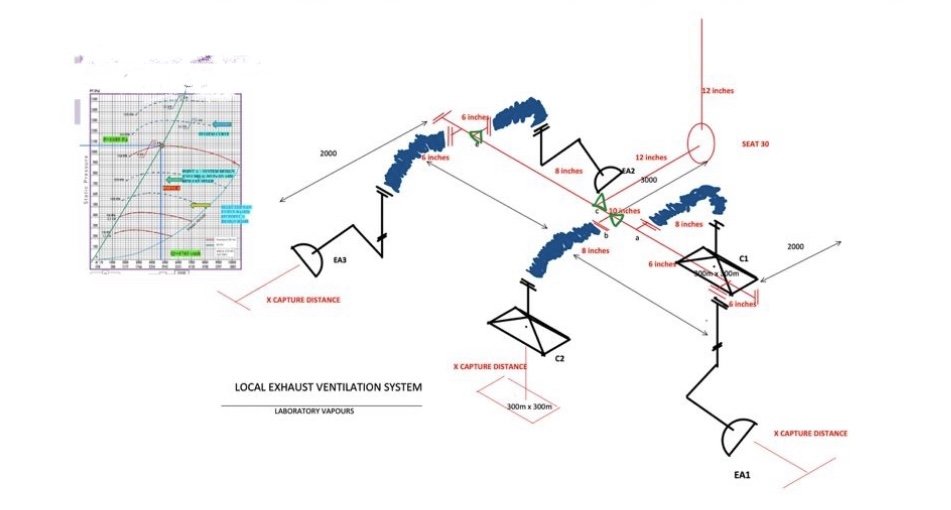

Before delving into the significance of proper design approaches, it's important to comprehend what fan curves are and how they influence the selection process. A fan curve is a graphical representation of a fan's performance characteristics. It typically includes information about airflow (in cubic feet per minute, or CFM) and static pressure (in inches of water column, or in. w.c.) at different operating points. The fan curve helps you visualize how a particular fan performs under various conditions.

A typical fan curve consists of two primary curves:

1. System Curve: This curve represents the system's resistance to airflow. It takes into account factors such as ductwork, filters, and other obstructions in the airflow path. The system curve is unique to each ventilation system and is crucial for understanding the fan's required performance.

2. Fan Performance Curve : This curve illustrates how the fan behaves in terms of airflow and pressure at various operating points, including its peak efficiency and maximum airflow.

Proper Fan Selection with Fan Curves

Now that we have an understanding of fan curves, let's explore why they are crucial in the fan selection process:

1. Matching Fan to System Requirements: Every ventilation system has specific requirements for airflow and pressure. The fan curve helps identify the operating point at which the fan should operate to meet these requirements. Selecting a fan that matches the system curve ensures optimal performance.

2. Efficiency Optimization: Fan curves allow you to pinpoint the fan's peak efficiency point. Operating the fan at or near this point ensures energy-efficient operation, which can significantly reduce operational costs in the long run.

3. Avoiding Overloading: Overloading a fan can lead to decreased lifespan, increased maintenance, and reduced efficiency. Properly analyzing the fan curve helps prevent overloading by selecting a fan that can handle the system's resistance without strain.

4. Avoiding Underperformance : Conversely, underloading a fan can lead to inadequate ventilation and temperature control. Fan curves ensure you choose a fan that can provide the required airflow and pressure for the system.

The Role of Design Approaches in Fan Selection

While fan curves provide invaluable information for selecting the right fan, design approaches are equally critical. Here's why a proper design approach is necessary:

1. System-Specific Consideration: Each industrial or commercial facility has unique requirements, such as temperature control, contaminant removal, or process efficiency. A proper design approach takes these specific needs into account to ensure the fan selected is tailored to the application.

2. Ductwork and Layout Optimization :Designing the ventilation system layout and ductwork correctly is essential to minimize resistance and pressure losses. A well-designed system reduces the workload on the fan and enhances its overall efficiency.

3. Safety and Regulatory Compliance: Proper design also includes safety considerations. Fans should be placed and enclosed in a manner that prevents accidents and complies with safety regulations and standards.

4. Future-Proofing : Designing for future expansion or changes in ventilation requirements is essential. A well-designed system can adapt to evolving needs without requiring a complete overhaul.

5. Noise Control : In many industrial settings, noise levels are a concern. Designing the system with noise control in mind can result in a quieter working environment.

The Synergy of Fan Curves and Design Approaches

To achieve the best results in fan selection, it's crucial to recognize that fan curves and design approaches are not mutually exclusive but rather complementary. The two should be used in conjunction to ensure an efficient, reliable, and cost-effective ventilation system.

For example, when designing a system, the system curve is developed based on the layout, ductwork, and any obstructions in the airflow path. Once the system curve is established, it can be superimposed onto the fan performance curve to identify the ideal operating point for the selected fan.

Proper design also considers redundancy and backup systems to ensure that the facility can maintain critical operations even if a fan fails. This strategy, combined with fan curve analysis, helps to mitigate risks associated with fan reliability.

Additionally, design approaches help minimize the need for excessive dampers and throttling devices, which can increase pressure drops and decrease overall system efficiency. By reducing unnecessary resistance within the system, fan curves become even more effective.

In summary, the selection of industrial and commercial fans is a complex process that demands attention to both proper design approaches and fan curves. Fan curves provide critical information about a fan's performance, allowing for the selection of the right fan that matches the system's specific requirements and ensures efficiency and reliability.

Design approaches, on the other hand, consider the broader context of the ventilation system, taking into account layout, safety, noise control, and future adaptability. When combined with fan curves, these design approaches create a synergy that results in a well-optimized ventilation system that can effectively serve its intended purpose.

By approaching fan selection with this dual perspective, industries and commercial establishments can not only improve their operational efficiency but also contribute to a safer and more sustainable working environment. Proper fan selection, based on fan curves and design approaches, is an investment that pays dividends in performance, longevity, and energy savings.